Choosing the Right Flow Meter: A Comprehensive Guide

Flow meters play a vital role in both industrial and commercial settings, providing essential measurement of liquids, gases, and steam.

These instruments help businesses monitor flow rates, ensuring the efficient operation of systems in sectors such as water treatment, oil and gas, HVAC, Pharmaceutical and manufacturing. By accurately measuring the flow, companies can optimise processes, reduce waste, and ensure safety.

Why Choosing the Right Flow Meter Matters

Accuracy and Efficiency

Selecting the correct flow meter is vital for optimising both process efficiency and measurement accuracy. A properly matched flow meter ensures that flow rates are measured with precision, reducing the likelihood of errors that could disrupt operations. This precision leads to smoother processes and better control, particularly in industries where even minor discrepancies can result in significant issues.

Impact on Operational Costs

Choosing the wrong flowmeter can result in various financial implications. Inaccurate data can lead to poor decision-making, affecting production quality or safety. Additionally, mismatched meters are often prone to excessive wear, leading to frequent repairs or replacements, which increases maintenance costs. These factors can collectively drive up operational expenses.

Compliance with Industry Standards

Accurate flow measurement is also critical for regulatory compliance. Many industries, including pharmaceuticals, food processing, and water management, have strict regulations governing the accurate recording of flow data. Failure to meet these standards due to inappropriate flow meter selection can lead to penalties, fines, and even operational shutdowns. A properly selected flow meter helps ensure compliance, safeguarding the business from regulatory risks while maintaining operational integrity.

Choosing the right flow meter is thus crucial for maintaining efficiency, controlling costs, and adhering to regulatory standards.

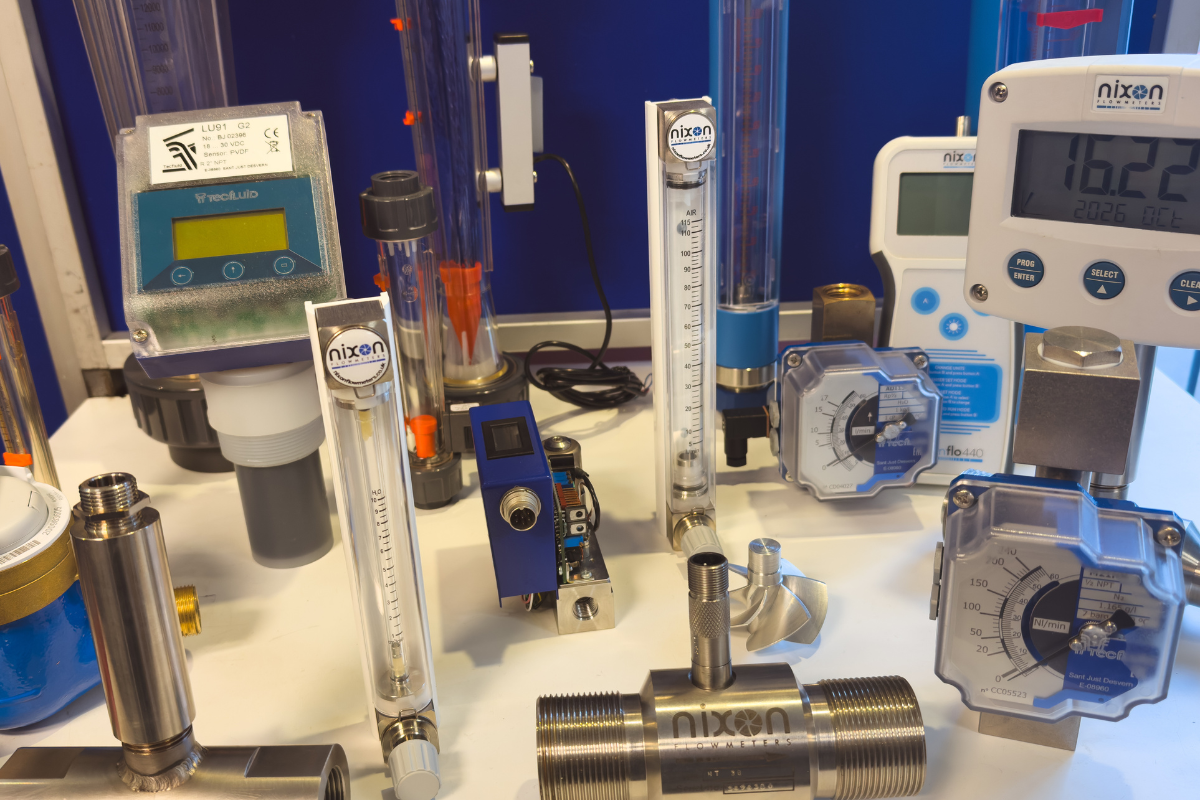

Types of Flow Meters

Mechanical Flow Meters

Mechanical flow meters measure fluid flow using moving parts. Common types include turbine meters, which utilise rotating blades to gauge flow rate, and positive displacement meters, which measure the volume of liquid passing through by trapping it in rotating chambers. Paddle wheel meters work similarly to turbine meters but are generally used for lower flow rates and simpler applications. Mechanical flow meters are typically very high accuracy devices.

Electromagnetic Flow Meters

Electromagnetic flow meters, or Magmeters, are ideal for measuring the flow of conductive fluids, such as water or wastewater. These devices use a magnetic field and electrodes to measure the voltage generated by the fluid moving through the meter, giving an accurate flow rate. Their non-invasive design means there are no moving parts, making them reliable for long-term use with minimal maintenance.

Ultrasonic Flow Meters

Ultrasonic flow meters measure flow by using sound waves. Transit-time meters calculate the time difference between two ultrasonic signals sent through the fluid, while Doppler meters detect changes in frequency caused by particles in the fluid. These meters are non-invasive, making them suitable for applications where the fluid cannot be contaminated.

Coriolis Flow Meters

Coriolis flow meters measure mass flow directly by detecting the force generated as the fluid moves through oscillating tubes. They are highly accurate and suitable for complex liquids, such as slurries or viscous substances, though they are more expensive.

Thermal Flow Meters

Thermal flow meters are used for measuring gases. They work by monitoring the rate at which heat is absorbed by the gas flowing over a heated sensor. They are typically applied in industries that handle gases like nitrogen or air.

Vortex Flow Meters

Vortex flow meters work by measuring the vortices formed as a fluid passes around a bluff body in the flow path. They are versatile, capable of measuring liquids, gases, and steam, and are often used in HVAC systems and process industries.

Key Factors to Consider When Choosing a Flow Meter

Fluid Type

The nature of the fluid you are measuring significantly impacts your choice of flow meter. Different types of flow meters are designed for specific fluids, whether it be liquids, gases, or steam. For example, electromagnetic flow meters are ideal for conductive liquids, while thermal flow meters are better suited for gases.

Flow Rate and Range

It’s essential to ensure that the chosen flow meter can handle the required flow rate and range within your system. Selecting a meter with a capacity beyond or below the actual flow rate can result in inaccurate measurements or device failure.

Pipe Size and Installation

The diameter of the pipe and the location of the flow meter installation play a key role in selecting the appropriate meter. Some meters, like ultrasonic models, can be installed non-invasively, while others require specific pipe sizes to fit.

Operating Conditions

Operating conditions such as pressure, temperature, and environmental factors (e.g., humidity, corrosion) can affect the performance and durability of flow meters. Certain meters, such as Coriolis meters, perform well in extreme conditions, while others may not be suitable for high temperatures or pressures.

Accuracy Requirements

Some industries, like pharmaceuticals or food processing, require precise measurements. In such cases, high-accuracy flow meters like Coriolis or ultrasonic models are preferred to ensure compliance and product quality.

Budget and Total Cost of Ownership

When choosing a flow meter, it's important to balance the initial purchase cost with long-term maintenance and operational efficiency. A more expensive meter with lower maintenance costs may offer better value over time compared to a cheaper alternative that requires frequent repairs or recalibration.

Advantages and Disadvantages of Popular Flow Meters

Mechanical Flow Meters

Mechanical flow meters are often the most cost-effective option, making them attractive for industries with tight budgets. However, they rely on moving parts such as turbines or paddles, which are prone to wear and tear over time. This results in more frequent maintenance and shorter lifespans, especially in applications involving abrasive or viscous fluids.

Electromagnetic Flow Meters

Electromagnetic flow meters, or magmeters, are highly accurate for conductive liquids such as water or wastewater. They offer a significant advantage due to their lack of moving parts, which translates to lower maintenance. However, they are unsuitable for non-conductive fluids like oils or gases, limiting their application range.

Ultrasonic Flow Meters

Ultrasonic flow meters provide a non-invasive solution, measuring flow without coming into direct contact with the fluid. This makes them ideal for applications where cleanliness or corrosion is a concern. However, they tend to be more expensive than other options, and their accuracy may depend on fluid properties and installation conditions.

Coriolis Flow Meters

Coriolis flow meters are known for their high precision, capable of directly measuring mass flow. This makes them ideal for high-accuracy industries like oil and gas. However, they come at a high cost and are often complex to install, which can increase upfront expenditure.

Vortex Flow Meters

Vortex flow meters are versatile, capable of measuring both liquids and gases. However, their accuracy can diminish at low flow rates, making them less suitable for applications requiring precise measurements of minimal flows.

Choosing a Flow Meter for Specific Industries

Water and Wastewater

Electromagnetic flow meters (magmeters) are commonly used in water and wastewater management due to their non-invasive nature and ability to measure flow accurately in conductive fluids. These meters provide reliable readings in harsh environments, making them ideal for large-scale water treatment and distribution.

Oil and Gas

In the oil and gas sector, Coriolis and ultrasonic flow meters are frequently utilised. Coriolis meters are prized for their precision in measuring mass flow, even in complex, high-pressure conditions. Ultrasonic meters are also favoured for their non-intrusive installation and ability to handle varying flow rates and pipeline sizes.

Food and Beverage

Hygiene is paramount in the food and beverage industry, making electromagnetic and ultrasonic flow meters popular choices. These meters ensure cleanliness and precision when measuring liquids, such as milk, juices, and other food-grade substances, without compromising sanitary conditions.

Pharmaceuticals

Pharmaceuticals demand extremely high accuracy and strict sanitary standards. Coriolis and ultrasonic meters are preferred due to their ability to provide precise measurements, crucial for ensuring correct dosing and maintaining product quality in highly controlled environments.

HVAC Systems

In HVAC (Heating, Ventilation, and Air Conditioning) applications, vortex and thermal flow meters are commonly used. These meters are well-suited to measuring gases and steam, offering a cost-effective solution for monitoring flow in energy-efficient heating and cooling systems.

Closing Remarks

When selecting a flow meter, several important factors must be considered, including the type of fluid being measured, the desired flow rate, installation requirements, and operating conditions such as pressure and temperature. There are various types of flow meters available, including mechanical, electromagnetic, ultrasonic, Coriolis, and vortex meters, each with its own advantages and suitable applications. These meters are used across different industries, from water treatment to food processing, and the right choice can significantly improve efficiency and accuracy.

Final Thoughts

Choosing the correct flow meter is essential to ensure operational efficiency, reduce maintenance costs, and enhance overall productivity. The wrong meter can result in inaccurate measurements, leading to wasted resources and higher expenses. By considering factors such as fluid type, accuracy needs, and the environment in which the meter will be used, businesses can make more informed decisions and avoid costly mistakes.

Nixon Flowmeters are happy to help

It’s crucial to assess your specific requirements before selecting a flow meter. Consulting with flow meter suppliers or experts can help you identify the best solution tailored to your industry and operational needs. Take the time to review your system’s demands, and explore the wide range of flow meters available to ensure you make the right investment for your business. Contact Nixon Flowmeters here.