06 March 2025

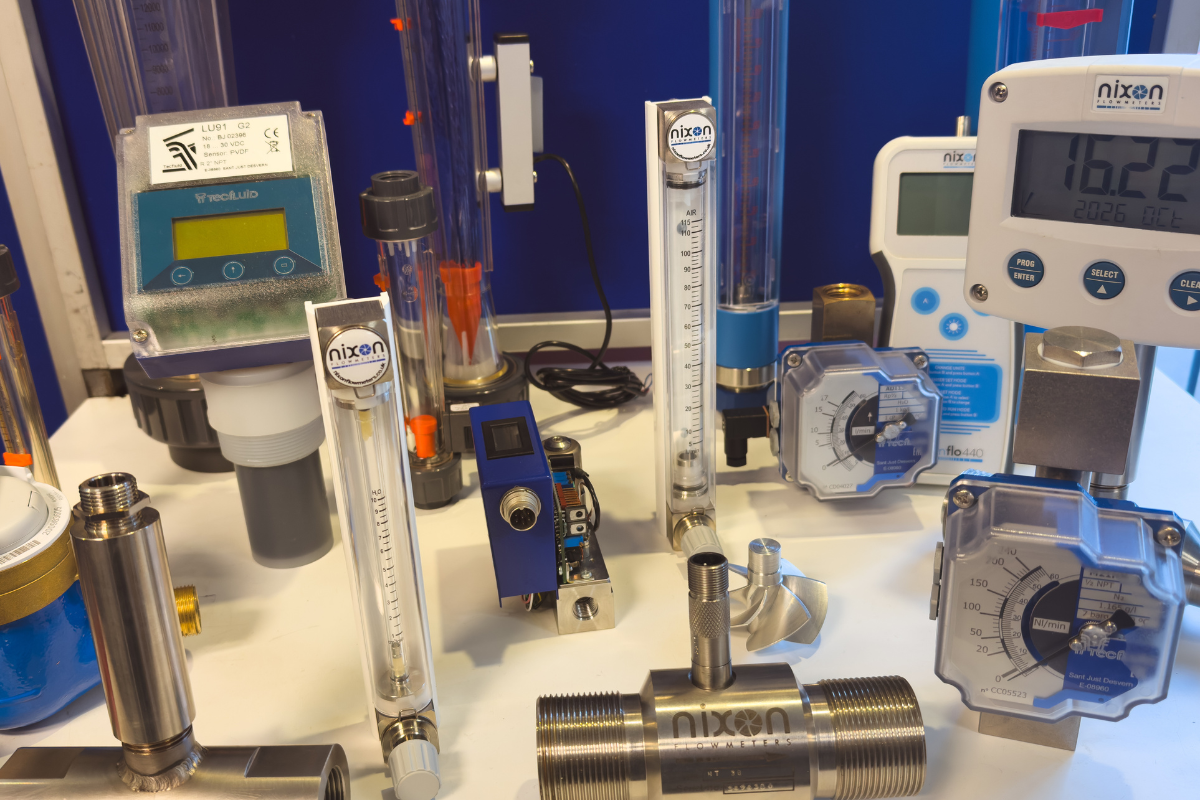

How to Choose the Right Water Flow Meter for Your Industry

Selecting the right water flow meter is a critical decision for businesses and industries that depend on accurate water measurement. Whether it is for monitoring consumption, optimising industrial processes, or ensuring regulatory compliance, choosing the most suitable flow meter can lead to increased efficiency, reduced waste, and significant cost savings. This guide aims to provide a comprehensive overview of how to select the best water flow meter based on industry requirements, fluid properties, and operational conditions.