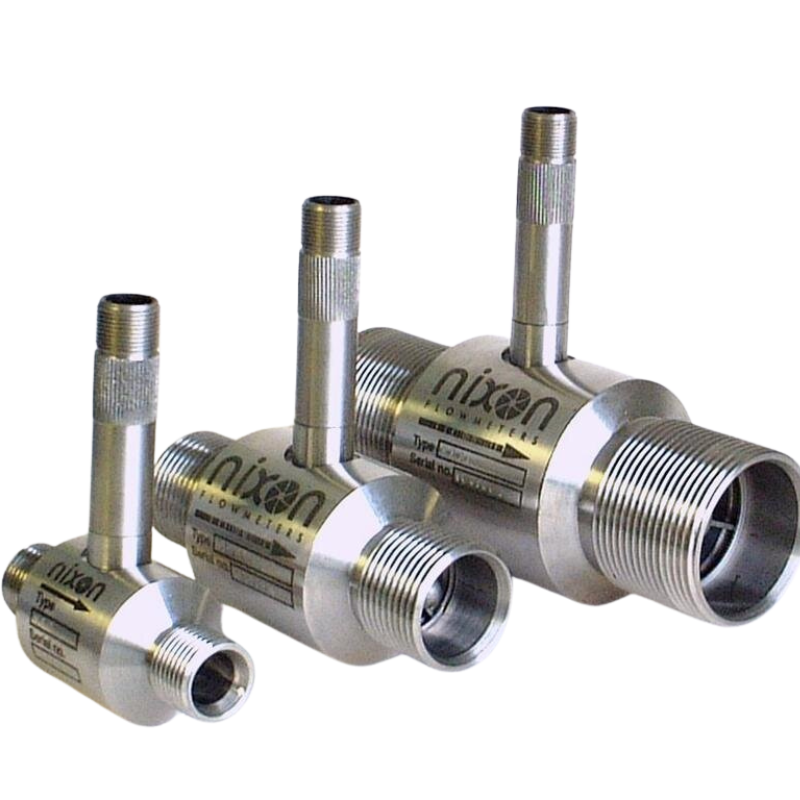

Turbine Flowmeters

The Nixon range of NT & BNO series turbine flow meters offers high accuracy and high reliability. Over 40 years, thousands of units have been sold to all classes of industry, and the Nixon turbine flow meter design has an excellent reputation for durability. Many leading flowmeter companies in the U.K. and abroad have the confidence to put their name on our range of turbine flow meters, a sign of the high regard in which the product is held.

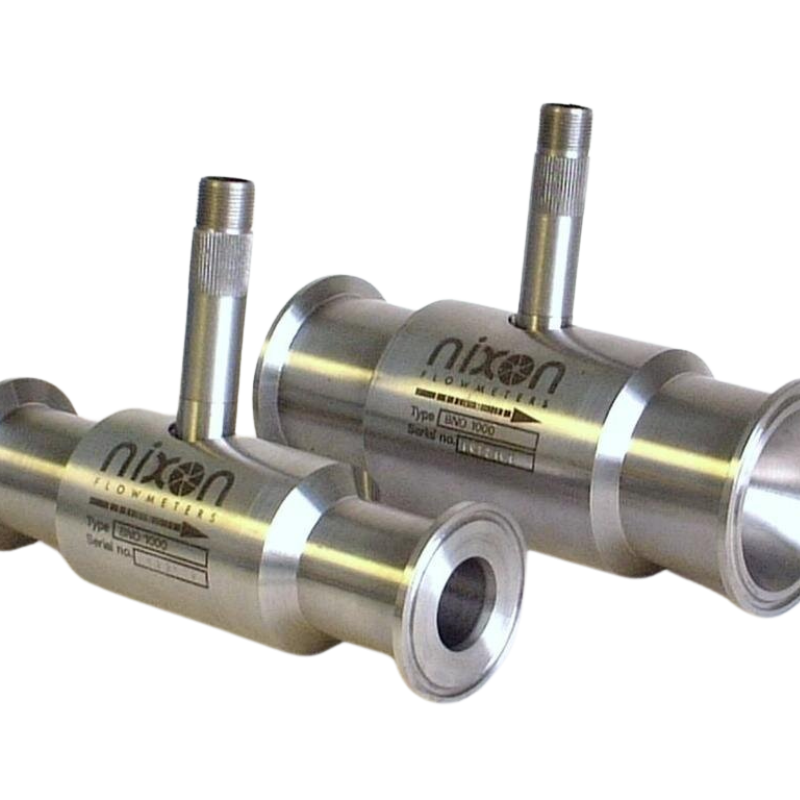

The range has been modified and extended over the last few years to provide a reasonably priced general purpose liquid flow meter. Versions suitable for dry Gas applications are also available. We produce flow sensors entirely in house to control quality and availability. The range is available on short deliveries, and popular sizes are held ex-stock. Available in a wide variety of body sizes, all turbine flow meters possess an electrical pulse output directly proportional to measuring flow rate. Remote flow indicating with alarms, totalising and batch control functions are available utilising our wide range of secondary electronic instruments. Pulse converters are also available, to provide a variety of different outputs. For example, 4-20mA, 0-10V etc. & also Modbus/HART protocol. Two different versions of our Turbine flowmeters- are available: - The NT industrial type & the BNO series, the latter of which is a dedicated Hygienic version, suitable for Pharmaceutical, food & other associated applications.

Operating Principle:

The metered fluid (or Gas) causes the helical magnetic rotor to revolve at a speed proportional to the flow rate. A magnetic pick-up coil, screwed into the exterior of the Turbine meter body, ‘picks-up’ on each blade of the rotor as it rotates, generating a pulse. The frequency of these pulses/revolutions can then be converted into a direct flow rate figure.

The liquid flow meters are suitable for use on lubricating or non-lubricating products of low to medium viscosity and are largely insensitive to density variations, pressure or temperature fluctuations. Turbine flow meter contact parts are produced from 316 stainless steel except rotors which must possess good magnetic qualities, and here 431 stainless steel (Ferralium in Hygienic versions) is used to produce pulses in the turbine flow sensor. Other materials are also available, to suit a wide range of process applications. Turbine flow meter can be machined & supplied with most types of end connections. Screwed BSP parallel thread with included 30 degree internal cones to BS5200, are standard but, most other types are also available. For example NPT, Ermeto, SAE, Swagelok & 1502 hammer unions, to name a few. Flanged versions are also available to ANSI, DIN or BS standards. The BNO Hygienic version can be supplied with Tri-clamp, RJT, Din11851 & other hygienic connections. Due to being manufactured entirely in-house, we pride ourselves on being able to offer special designs, to suit the end users specific requirements. A Subsea version is also available, supplied with Subconn (or alternative) connector. High Temperature versions up to 400 degC are available. High Pressure versions can be, rated to over 1500 bar.

Advantages of using Turbine Flow meters :

Suitable for both liquid & also gas flow measurement.Turbine Flowmeters can be manufactured with different bearing designs which make then suitable for lubricating & non-lubricating liquids & also those of low to medium Viscosity & also dry Gasses.

High Accuracy.

Turbine Flow meters have a linear accuracy to +/- 0.5% of reading, with a repeatability of +/- 0.1% of reading. This makes a Turbine Flowmeter one of the most accurate forms of flow measurement on the market today.

Installation in different orientations & flow directions.

A Turbine flowmeter can be installed in both vertical & horizontal orientations - taking into consideration the recommended installation requirements of 10 x diameter of straight pipe before the flow meter & 5 x diameter after the flowmeter. Bi-directional (quadrature) versions can be supplied using dual pick-up coils to monitor the flow in both forward & reverse directions.

Wide range of pipe sizes & end connections.

Both our NT & BNO Hygienic Type range of turbine flow meters can be supplied in sizes from 3/8” up to 6” in size. All out Turbine flowmeters are machined in house from solid round 316L Stainless Steel bar. As a result, our Turbine meters can be supplied with a wide range of different end connections. The standard is a BSPP male thread, with 30 degree internals cone. Other examples are flanged Ansi or din, NPT, Ermeto, JIC, wafer design & various high Pressure couplings e.g. Weco 206 & 1502 hammer unions. Our dedicated Hygienic BNO series Turbine meter can e supplied with most types of hygienic coupling. For example Tri-clamp, RJT, din 11851 etc. It really is a case of whatever type of connection you require, we can machine it for you.

Low Pressure drop.

The construction of a Turbine flowmeter allows for a very low Pressure drop, typically around 200-500 mbar, depending on size & liquid being measured.