Michael Faraday & Electromagnetic Flow Meters

In 1831, Michael Faraday discovered Electromagnetic Induction. This became known as Faraday's law. As a result, we now have electromagnetic-type flow meters.

If an electrical conductor is moved into an electrical field, an electrical voltage is induced in the conductor. This is perpendicular to the direction of motion & the magnetic field, whose magnitude is then proportional to the magnetic field strength & velocity of the movement.

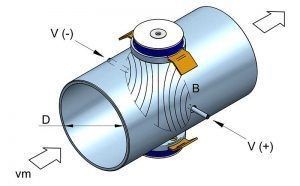

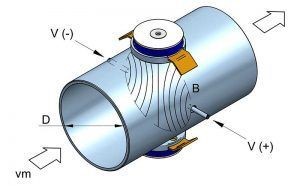

The following diagram provides a slightly simpler explanation.

A voltage V is induced between a pair of electrodes when a conductive liquid flows in a pipe of diameter D at an average velocity vm, through a magnetic field B (which is perpendicular to the flow direction). This voltage, proportional to the average velocity of the liquid, is acquired by the electronic converter in order to be processed and converted to a flow rate measurement.

V = B ・ vm ・ D

V = Voltage across the electrodes

vm = Liquid velocity

B = Magnetic field strength

D = Pipe diameter

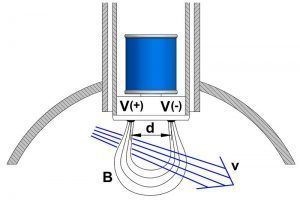

When an electrically conductive liquid flows through a magnetic field, perpendicular to the flow direction, it induces a voltage V proportional to the liquid velocity.

Two electrodes in contact with the liquid and positioned perpendicularly to the magnetic field, sense this voltage V.

V = B ・ v ・ d

V = Measured voltage at the electrodes

v = Liquid velocity

B = Magnetic field density

d = Distance between electrodes

Benefits to using Electromagnetic Flowmeters

Low Pressure drop

Because there are no moving parts inside the flow meter, the Pressure drop is very low. This makes them ideal for applications where there isn’t much upstream Pressure in the system.

Suitable for both clean & dirty liquids

No moving parts also means Electromagnetic flow meters are suitable for liquids where there could be the presence of suspended particles, solids etc.

Installation

So long as the pipework is full/flooded, Electromagnetic flowmeters can be installed in both horizontal & vertical pipes (when installed vertically, a downwards flow is not recommended).

Pipe Sizes

Electromagnetic Flow meters can be supplied to cover from very small DN3mm bore pipe, up to much larger DN2000mm sizes. The Flomat insertion Flowmeter, because of its very small form factor, makes for a very cost effective solution for flow measurement in very large bore pipework.

Digital displays & outputs

Electromagnetic flowmeters can be supplied with a digital display, showing flowrate, total & also accumulated total. These can be direct mounted on top of the flowmeter itself or, separate. A wide variety of outputs are available, for example 4-20mA, pulse, high & low alarm contacts & also HART/Modbus versions.